Time Efficient. Cost Effective. Comprehensive.

The Power of Infrared

An infrared camera is a non-contact device that detects infrared energy (heat) and converts it into an electronic signal, which is then processed to produce a thermal image or video, on which you can perform temperature calculations. Heat sensed by an infrared camera can be very precisely quantified, or measured, allowing you to not only monitor thermal performance, but also identify and evaluate the relative severity of heat-related problems.

Fast Turnaround

Schedule your inspections with ease, and get the pertinent information you need. Our rapid turnaround time makes all the difference.

Latest Technology

Our highly trained and professional thermographers use the latest advances infrared technology and are Level 1 & 2 Certified.

Flexibility

We tailor our services to meet your needs. Let us know what you're looking for and how we can help out.

82% of companies experience at least one unplanned shutdown over a three-year period.²

Reduce the risk of equipment failure and unnecessary shutdowns by detecting problems in your systems. A thermal imaging survey can help identify defects early helping your business to reduce labour costs and unnecessary shutdowns while increasing workplace safety.

Infrared Waves

We encounter infrared waves everyday. Although invincible to the naked eye, humans can detect these waves as heat, using infrared technology. Find out how infrared cameras work.

Take a closer look.

ProSCAN employs the latest infrared technology, using FLIR Canada’s industry proven technology. Our non-contact measurement and imaging tool displays temperature anomalies on screen, allowing our technicians to pinpoint the source of problems quickly and efficiently.

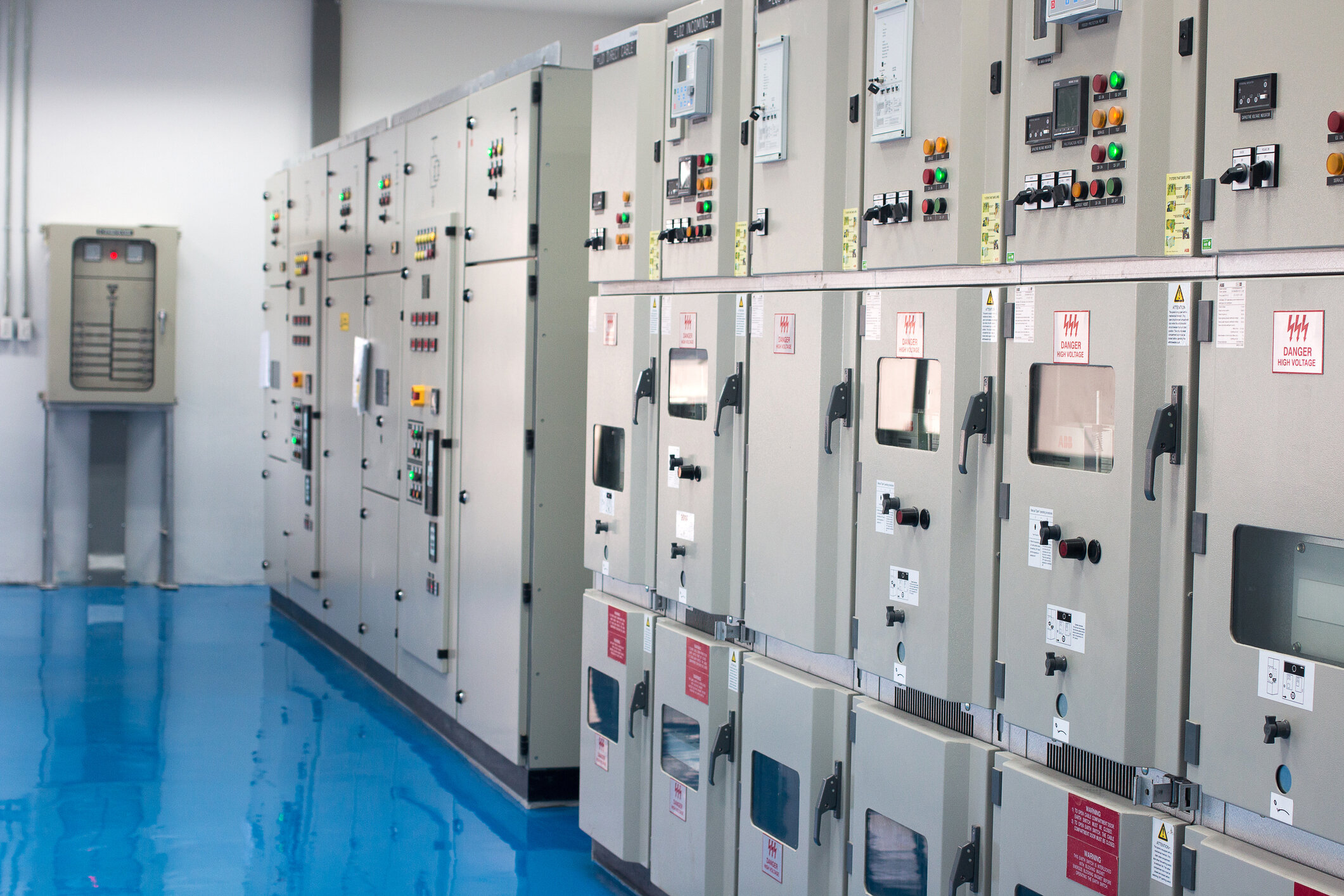

Bring hidden issues to light with thermal imaging

Benefits of Thermal Imaging

A non-invasive infrared survey can help you

Identify.

See initial signs of danger. A thermal imaging camera allows you to quickly scan large areas, looking for hot spots on machinery or electrical systems and building structures that could indicate a potential problem.

Minimize.

When seconds count. Thermal imaging can help you quickly target the source of the problem for the customer to make informed decisions and/or immediate repairs. A solid predictive maintenance program can make the difference between meeting or missing production deadlines.

Reduce.

Reduce risk of injury and increase safety. Thermal images provide visual proof a fault existed and was properly repaired. Including the images and measurement data in your reports will help to document your work and increase customer confidence.

Our Expertise

ProSCAN’s Thermographers are highly trained in accordance with the Infrared Training Center. This accreditation is the gold-standard qualification within the thermography industry

Our thermographers are Level 1 & 2 certified

Powerful Reporting.

ProSCAN uses a powerful reporting solution to streamline your inspections and not only highlight critical repairs but offer predictive and trending analysis. Our dynamic reporting process creates a new level of efficiency saving time on the job and at the desk. Our reports accurately track thermal performance over time with easy to understand charts and graphs.

Why use Infrared?

If you are a property owner, property manager, real estate investor or facilities manager, infrared testing adds an invaluable dimension to your building diagnostics and preventative maintenance program. ProSCAN can evaluate and protect property and equipment investments by finding the problems before it is too late.

²Unplanned downtime affecting 82% of businesses. (n.d.). Retrieved from https://www.themanufacturer.com/articles/unplanned-downtime-affecting-82-businesses/

Find Out More

ProSCAN is dedicated to providing professional, cost effective and state of the art commercial, industrial and residential inspections with service excellence. Discover the ProSCAN Advantage today

1.855.916.7226 / 604.916.7226

info@proscaninspections.ca